-

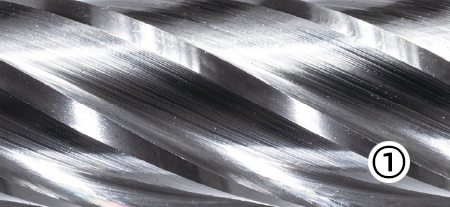

Cut type 1 - Aluminium

Particularly suitable for working on aluminilum magnesum, plastic, and hard rubber. Gives high cutter eff clency,with goodremoval of materlal. The specili c features of this type of cut facilitate rapid removal of chips preventing these from clogging the tool.

-

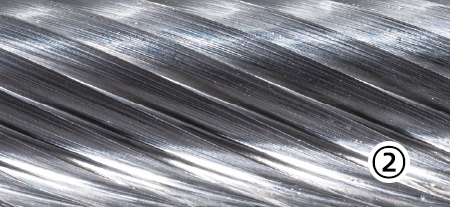

Cut type 2 - Course

This type of cut is intermediate between cut 1 and cut 3 and,it is recommended for soft malterials, bronze,brass, tin, zinc,copper and other easily removable materials. For long chipping material this cut should be used with chip breaker.

-

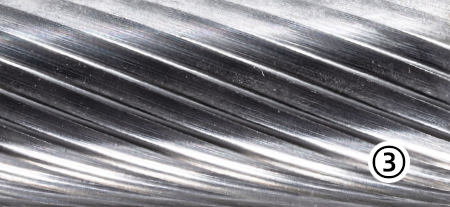

Cut type 3 - Medium

Standard cut. Sultable for steel (including tempered) cast steel,weld seams,and in general almost all metllic materials.To gether with optimum effi clency,it gives a good surface finish.

-

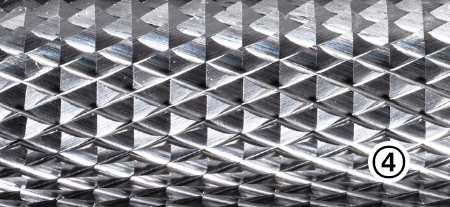

Cut type 4 - Diamond

Recommended for high alloy steel,stainless steel,magnestum alloys, grey cast iron and CrNi steels.lts particular geometry allows considerable material penetration with a removal capacity greater than the Standard cut. it avoids the formation of true proper chips pulverising the removed material and thus avoiding the associated disadvantage for the operator during worxing.

-

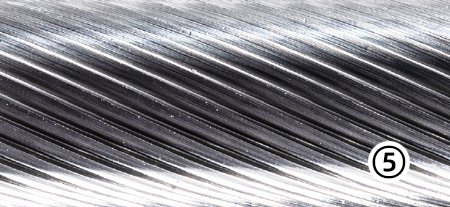

Cut type 5 - Dense

Dense tooth pattern, especially suitable for tempered steel below 66HRC and situations with high requirements for material surface quality.

-

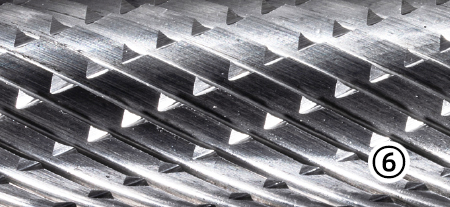

Cut type 6 - Double

Universal cut suitable for working on almost metallic materials,including tempered steels and corrosion resistant material.Reduces vibration and gives a betler control of the cutter during working. Considerable removal capacity with good surface finish.